Benefits of Using a Hogback in a Screw Feeder

Question

I have a screw feeder located in a pit for railcar unloading. Sometimes when I open the gates of the railcar and flood the pit with a bulk material, the screw feeder will not start. I have to dig material out of the pit to get the screw to operate. I need my screw feeder to operate under all conditions. Someone mentioned to me that I need to add a hogback. What is a hogback?

Answer

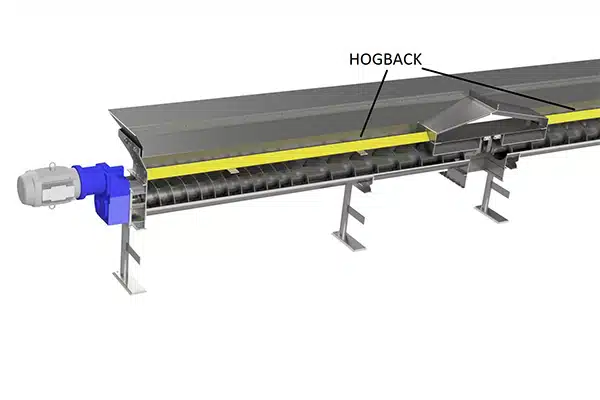

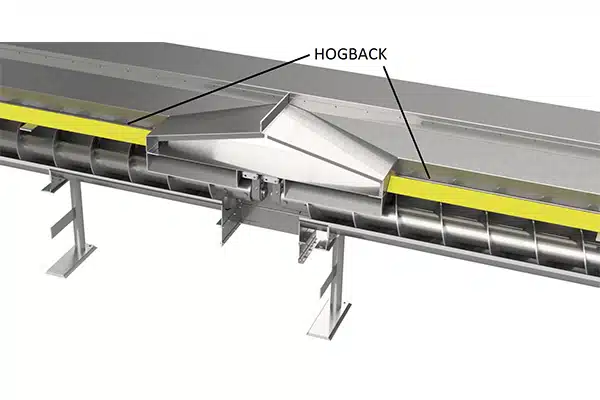

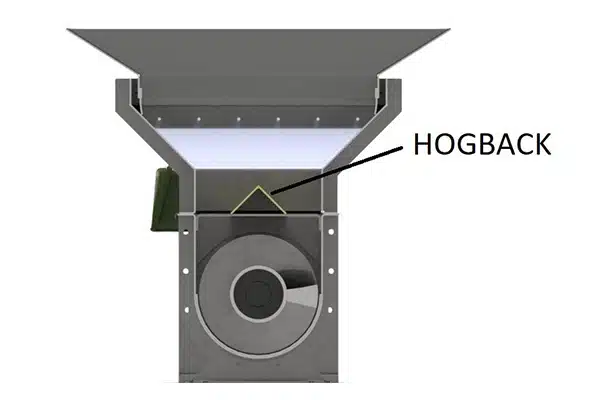

A hogback is a simple yet highly beneficial addition that will save time, money, and extend the life of your screw feeder. Covering the width of the center pipe of the screw and sometimes some of the screw flights as well, a hogback is an inverted structural or formed angle similar to a roof peak. A hogback relieves the head load force of the bulk material on the feeder screw, while also preventing screw deflection and shock load.

Hogbacks can be constructed from carbon steel, stainless steel, or even “AR” (abrasion resistant) material. As bulk materials discharge from the railcar hoppers, the hogback deflects the material from directly impacting the feeder screw. The bulk material flows around the hogback and into the flights of the screw. Hogbacks can be welded permanently in place or bolted to the trough for easy removal when maintenance is required.

A Hogback is an Inverted Structural or Formed Angle Similar to a Roof Peak

A Hogback Relieves Head Load Force of Bulk Material on Feeder Screw

A Hogback Covers the Width of the Center Pipe of the Screw