Coupling Bolt Wear and Failure

Question

I have a vertical screw conveyor in a batching operation where I convey food product to a surge bin. The surge bin must be filled at least 20 times per hour. The vertical screw conveyor ran fine for about 3 months until we started seeing coupling bolt wear and ultimately screw failure at the drive end. Please see the attached photos. How do I prevent the wear and failure, so I don’t have to worry about downtime?

Answer

Thank you for the question and for sending photos of the wear and failure. Cycling the vertical screw conveyor on and off 20 times per hour is creating a “hammering effect” on the drive end connection to the screw. The CEMA 2-bolt coupling shown in the photos is subjected to full-motor torque at every start up. The “hammering effect” is loosening up the connection between the coupling bolts and screw. As the clearance increases, the “hammering effect” becomes greater, until the coupling bolts or screw fails.

Fortunately, there are several possible solutions for eliminating the problem and preventing downtime.

- Reduce Cycle Times – Reducing the number of starts and stops will reduce the “hammering effect” and increase the life of the vertical screw conveyor.

- Use Soft Start – A typical TEFC motor generates at least 150-percent of motor voltage and torque at start up when started with full voltage and current. A soft start provides a ramp up of voltage and current, greatly reducing the “hammering effect”.

- Use Proper Coupling Bolts – The coupling bolts in the photos you sent clearly show that the wrong coupling bolts were used for the application. Proper coupling bolts are very important for long-term operation of screw conveyors. The shank length of a coupling bolt must be equal to the pipe diameter. Bolt threads are not allowed in the connection area. Threads in the connection area create clearance and reduce the shear strength of coupling bolts.

- Use 3-Bolt CEMA Connection – Changing from a standard CEMA 2-bolt to a 3-bolt connection increases the torque rating of the drive connection by 50-percent. The torque load at start up is now divided by 3 coupling bolts instead of 2, effectively distributing the torque load. Also, a 3-bolt connection provides a longer engagement between the drive shaft and screw, providing more stability.

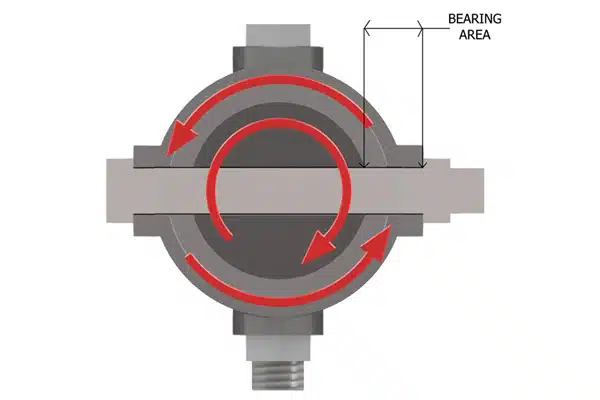

- Add Bolt Pads to Screw – Bolt pads add more bearing area to the CEMA 2-bolt or 3-bolt connection and greatly increase the torque rating of the connection. Greater bearing area also reduces the possibility of coupling bolt wear as there is a greater shear surface area.

Shank of Coupling Bolt is Worn in Bearing Area Due to Repeated Starts and Stops of Vertical Screw Conveyor

Use of Improper Coupling Bolts Contributed to Screw Failure

Repeated Stops and Starts Along with Improper Coupling Bolts Caused Screw Failure

Coupling Bolt Shank Length is Always Equal to Pipe Outside Diameter

Typical Screw with KWS Bolt Pads

Bolt Pads Increase Bearing Area and Torque Rating of Connection