Recommended Screw Orientation at Hangers

Question

We have several screw conveyors at my plant that have been operating successfully for many years. The internal components are worn out and we recently purchased replacement screws, hangers, shafts, and bearings. We will reuse the existing troughs, trough ends and drive unit. When we install the new screws, does it matter if the flights are matched up across the hanger?

Answer

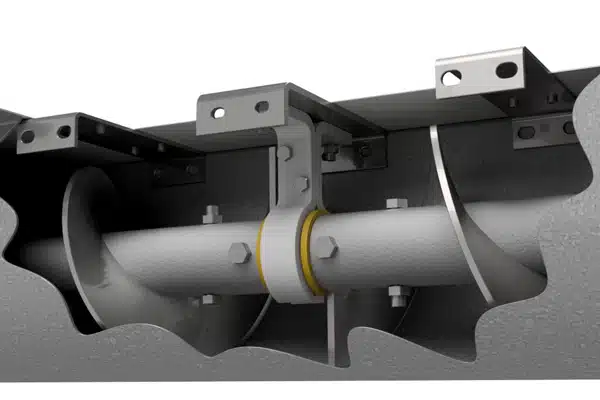

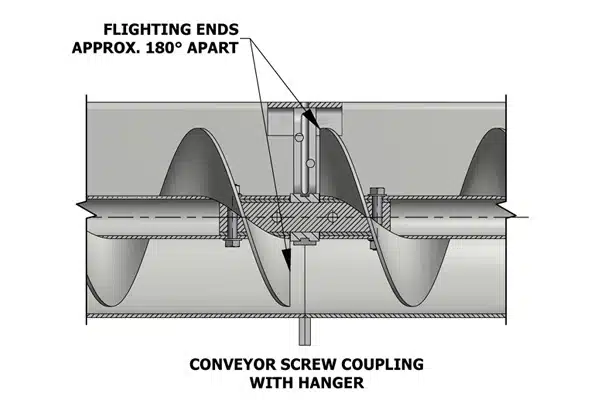

When screw conveyors are designed with intermediate hanger bearings, KWS recommends offsetting the screw flight ends at 180-degrees from each other at the hanger. With this arrangement, the downstream screw begins to convey the bulk material in half of a rotation, allowing the bulk material to work past the dead space beneath the hanger. Sometimes, the combination of screw pitch and length may result in an offset that is slightly more or less than 180-degrees due to where the flight terminates on a screw. If the screw flight ends were in line with each other at the hanger, a full rotation of the screw is required to convey the bulk material by the downstream screw.

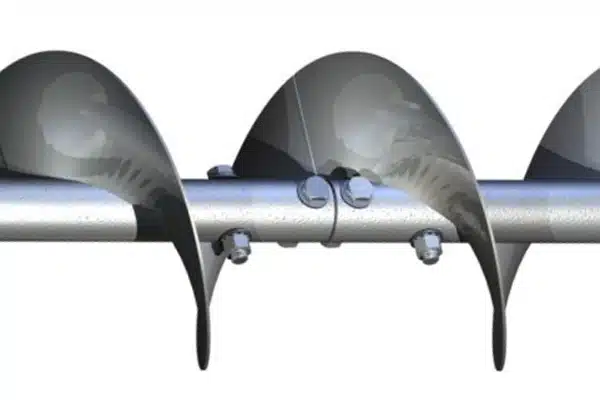

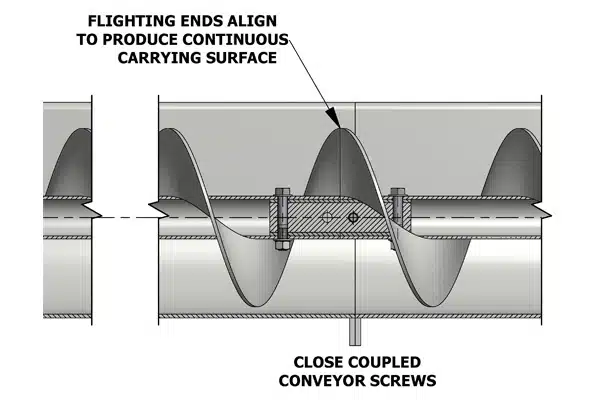

Many applications such as rendering do not use hangers. Joining two or more screws together without the use of a hanger is called close-coupled-and-clocked. Clocking or matching up screw flight ends creates a continuous helix and is very efficient for conveying bulk materials. Close-coupled-and-clocked screw assemblies require the use of a trough liner to support the screws since no hangers are present.

KWS Recommends Offsetting Screw Flight Ends 180-Degrees from Each Other

Downstream Screw Begins to Convey Bulk Material in Half of Revolution

Close-Coupled-and-Clocked Screws Create Continuous Helix

Close-Coupled-and-Clocked Screws Require the Use of Trough Liners to Support Screw Sections