Screw Conveyor Hangers and Bearings for Heavy Duty Applications

Question

I have several screw conveyors in my plant conveying minerals from a grinding operation to further processing. Hangers and hanger bearings are a constant maintenance headache. Which style screw conveyor hanger and bearing is better suited for my heavy-duty application?

Answer

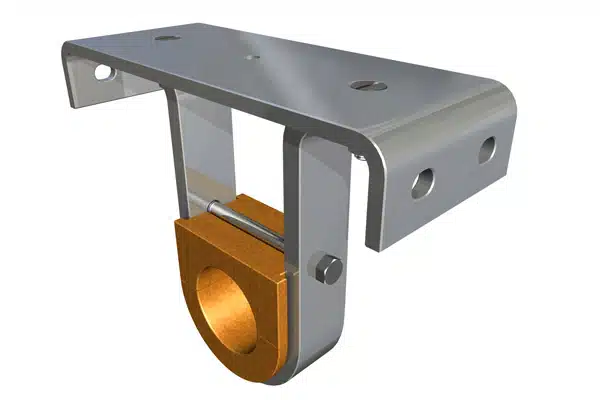

For heavy-duty applications where bulk material density exceeds 70 lbs. per cubic foot, KWS recommends using style 216 hangers and bearings when compared to style 226 hangers and bearings. Style 216 hangers and bearings provide a more robust design and higher weight capacity when compared to style 226 hangers and bearings.

The double body bar of the style 216 hanger is designed to withstand heavy loads and provide rigidity and strength. The single body bar of the style 226 hanger is better suited for light to medium duty applications while also allowing minimal obstruction to bulk material flow.

Style 216 and 226 hangers are the most widely used in the industry. KWS stocks all CEMA standard sizes in both style 216 and 226 hangers and bearings. Reach out to KWS today for same day shipment!

216 Double Body Bar Withstands Heavy Loads and Provides Rigidity and Strength

226 Single Body Bar Provides Minimal Obstruction to Bulk Material Flow