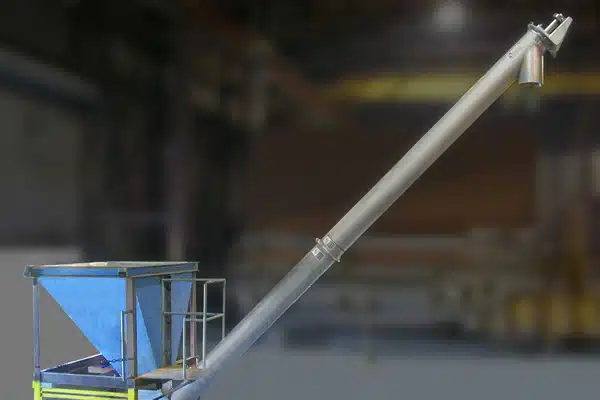

Non-Split Tubular Troughs for Screw Conveyors

When conveying bulk materials at angles steeper than twenty degrees, tubular screw conveyor housings or troughs are typically recommended and used. Non-split tubular troughs can be used to improve conveying efficiency on inclines by containing the bulk material in the screw and preventing the material from falling backward over the top of the screw which takes place in U-shaped troughs. The tubular trough design reduces turbulence, cross-sectional loading, and wasted power which can occur in standard screw conveyor U-shaped troughs.

In both inclined and horizontal installations, non-split tubular troughs offer a completely sealed housing for use in weather-tight, vapor-tight, and dust-tight applications. The non-split trough design also minimizes leakage when conveying very fine, free-flowing powder-like bulk materials like sodium bicarbonate, talc, or flour. Non-split tubular troughs reduce the ingress of moisture when conveying hygroscopic materials like adipic acid, carbon black, or salt. Likewise, they are used to hold internal pressure in a screw conveyor or screw feeder. ASME-coded non-split tubular troughs are also available from KWS.

Non-split tubular troughs are manufactured by rolling a cylindrical tube and continuously welding it at the seam. Alternatively, it can be spouting or ASTM standard pipe that is cut to length for the specific application.

Non-Split Tubular Troughs are Used in Weather-Tight Applications

Features:

Wide Variety of Materials – KWS non-split tubular troughs may be constructed out of carbon steel, abrasion-resistant steel, stainless steel, or special alloys, based on the specific application.

Benefits:

Improved Conveying Efficiency – Non-split tubular troughs minimize overall clearance around the screw and trough when compared to U-shaped troughs reducing bulk material fallback and increasing conveying efficiency on steep inclines.

Elimination of Feeder Shroud – In screw feeder applications, non-split tubular troughs act as a feeder shroud which would be required in U-shaped troughs. The tubular cross-section allows for an accurate feed rate when metering from a hopper, bin, or silo and prevents bulk materials from flooding past the inlet and the screw.

KWS Provides ASME Coded Non-Split Tubular Troughs for Many Applications

Conveying Efficiency is Improved for Inclined Screw Conveyors by Using Non-Split Tubular Troughs

Non-Split Tubular Troughs are Perfect for Inclines Greater than 20-Degrees