KWS Replaces Failed Screw at Georgia Pacific Mill in Brewton, AL

Introduction

The Georgia Pacific mill in Brewton, AL primarily produces a variety of paper products that include containerboard, kraft paper, and recycled paper products. A crucial screw conveyor in the transport of reburned lime & fresh lime had seen continued failures and a replacement screw was needed immediately.

KWS Replacement Screw Eliminates Problems with Existing Screw

Challenge

The current screw was failing due to fatigue at the flange connections, and field measurements indicated that excessive shaft runout was likely the culprit. Additionally, the screw conveyor was operating at temperatures reaching 500-degrees F, with axial thermal expansion of over 1-inch for the 35-foot-long screw. Since the screw conveyor had no space to accommodate this thermal expansion, cyclical bending loads contributed significantly to the excessive runout.

KWS Advantage

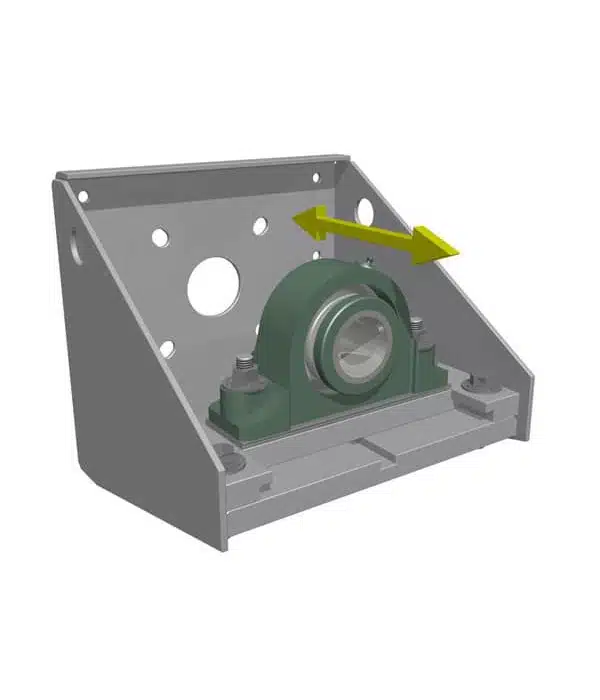

The new KWS replacement screw assembly was a drop-in replacement with no modifications to the existing housing and drive unit. Using proven KWS design standards, KWS engineers provided a superior screw with full penetration welds on the flange-to-pipe connections that will not fail. Flanged drive and end shafts were machined from a single piece of bar stock to provide an unbreakable connection. The completed screw assembly was tested and straightened in a lathe to within 0.0050-inches TIR. To accommodate for thermal expansion, KWS provided a custom slider base trough end for the tail end to allow the screw and pillow block tail bearing to expand and contract axially.

Testimonial

"The replacement screw assembly and slider base trough end provided by KWS has been installed and is working flawlessly. The design and fabrication quality are the best we have ever seen. Thanks for the great work. KWS can expect to see more business from our mill."

Flanged Drive and Tail Shafts are Machined from Single Piece of Bar Stock and Will Not Fail

Flanged Tail Shaft is Bolted to Screw Assembly

Slider Base Allows for Axial Thermal Expansion

KWS Slider Base Trough End