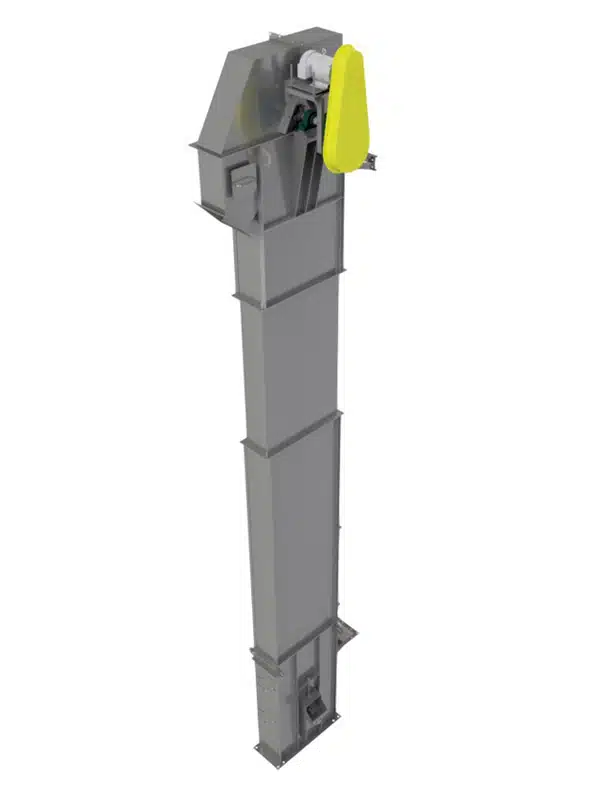

Bucket Elevator for Inland Empire Paper Company

General Description

Inland Empire Paper (IEP) upholds a proud tradition as a manufacturer of high quality newsprint and specialty paper products. IEP has continuously operated in Millwood, Washington since 1911. Today IEP supplies paper to over 160 customers throughout the western United States and produces over 500 tons of newsprint every day.

IEP focuses on efficient utilization of many natural resources in their production process including air, water, and energy. Recycled materials such as wood chips and old newspapers are the basic components of paper.

In this application, ash is produced from IEP’s Fluidized Bed Boiler (FBB) system that consumes approximately 50 dry tons per day of paper sludge residuals. The paper sludge residuals are generated primarily from IEP’s de-inking process of recycled papers. The residuals are collected from IEP’s wastewater treatment system and de-watered in screw presses to approximately 60-percent moisture content then sent to the FBB for combustion. Ash is collected from various locations in the combustion system and conveyed pneumatically to a silo for storage in preparation for shipment. IEP’s ash is beneficially re-utilized as a cement admixture, in compost or is pelletized for use as a soil amendment.

Ash Pellets are Conveyed Vertically in New KWS Bucket Elevator

Design Parameters

- Product Type: Ash Pellets

- Design Temperature: Ambient

- Material Density: 66 Lbs. per Cubic Foot

- Capacity: 171 Cubic Feet per Hour

- Duty: Intermittent

KWS Advantages

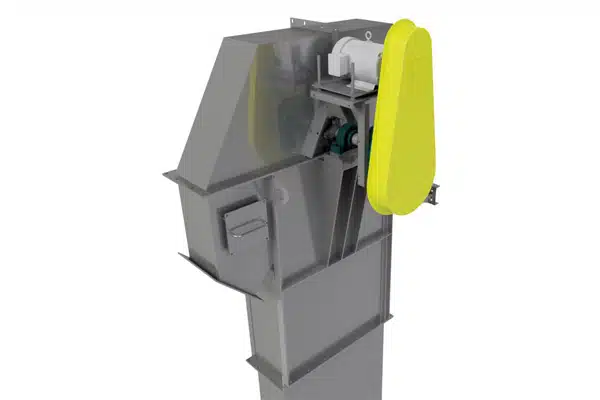

KWS engineers worked closely with the engineers at Inland Paper throughout the entire process to ensure the bucket elevator would fit in the existing footprint. KWS provided a full set of Autodesk Inventor 3D models and 2D drawings during the review process to check for design and interference issues. Together, we were able to ensure the installation would go smoothly with no interference issues with existing equipment.

KWS Special Features

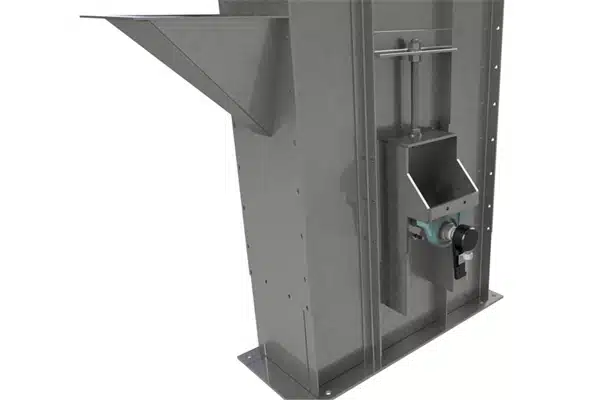

The new KWS bucket elevator was extremely heavy duty in construction to handle the abrasive ash pellets. A screw type take-up was located in the boot section and externally mounted for easy accessibility and maintenance. Take-up adjustments are made on each side independently to aid in belt alignment and tracking. All adjustments are made using common tools.

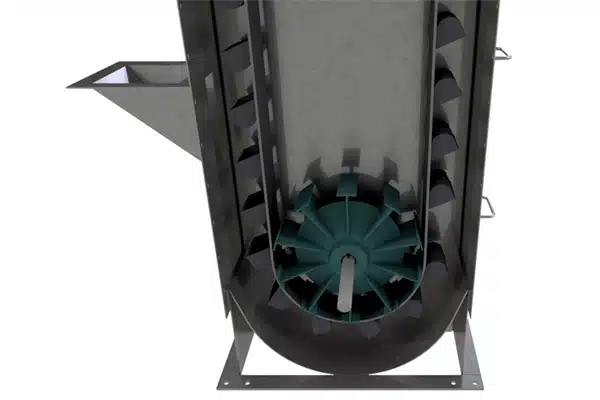

The belt and buckets were carefully selected based on the application to provide a long-lasting system and avoid maintenance shutdowns. Style AA high-impact ductile iron buckets were used to provide a very robust design.

A Whirligig zero speed switch warns operators of equipment malfunction through detection of zero speed and provides a signal that is used in upstream control panels to shut down machinery in case of a sudden jam or failure. The process may be halted to prevent damage or plugging in the equipment.

Testimonial

"KWS is a very professional organization and provides exceptional quality equipment. We will be purchasing future equipment from KWS."

Doug Krapas, Environmental Manager – Inland Empire Paper Company

Screw Take Up is Located in Boot Section Along with Whirlygig Speed Sensor

Style AA High-Impact Ductile Iron Buckets are Ideal for Handling Abrasive Ash Pellets

New KWS Bucket Elevator was Extremely Heavy Duty in Construction