Conveying Dewatered Biosolids at Jessamine Creek WWTP

General Description

Jessamine Creek WWTP is in Nicholasville, KY. The facility is increasing its capacity from 4.5 to 7.1 million gallons per day (MGD). The plant reached its capacity in 2019 and the increase will help with further development in Nicholasville and the surrounding communities. The plant has installed approximately $9 million in new processing equipment.

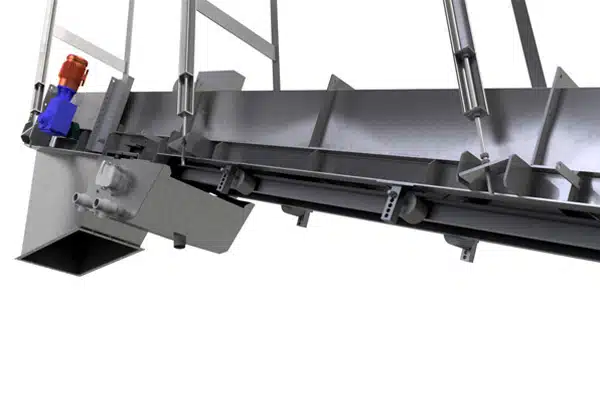

A new cleated belt conveyor was added to convey dewatered biosolids from an additional belt filter press to a new screw conveyor for truck load. Dugan & Meyers in Louisville, KY provided consulting engineering and construction installation on the project and worked closely with KWS. KWS provided a solution that will have minimum maintenance and downtime.

Belt Conveyor Receives Biosolids from Belt Filter Press

Design Parameters

- Product Type: Dewatered Biosolids

- Material Density: 60 to 90 Lbs. per Cubic Foot

- Capacity: 31 Cubic Feet per Hour

- Duty: 24 Hours per Day, 7 Days per Week

KWS Advantages

KWS has an extensive successful history for solving problems at wastewater treatment facilities throughout the US. Engineers from KWS worked directly with Dugan & Meyers to develop the specifications and create the layout for the new belt conveyor, screw conveyor, supports, and chutes. A complete system with connections to the building was included in the design process. Autodesk Inventor files were supplied of the units so Dugan & Meyers could include them in their 3D model of the plant to make sure everything would connect and fit-up properly.

KWS provided on-site training during installation and startup of the new belt conveyor and screw conveyor. Training was provided by a KWS Project Manager familiar with the project and design requirements.

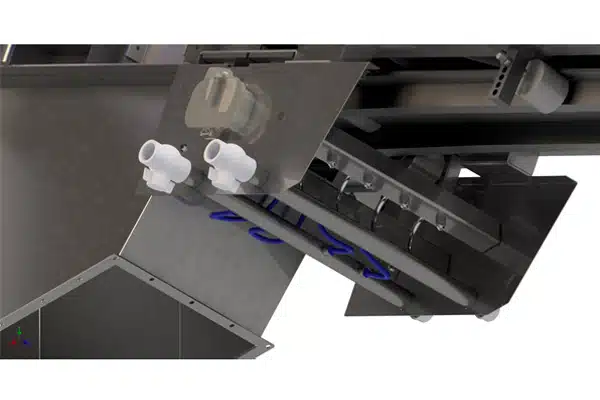

Spray Box Keeps Belt Clean

KWS Special Features

KWS provided a new belt conveyor along with instrumentation and controls to transfer biosolids from the filter press to a screw conveyor. The belt conveyor was designed and manufactured with a formed channel frame with a belt beater and spray box mounted to the under side of the head pulley to knock sticky material off the belt. The carrying idlers were mounted on 4-foot centers for maximum support of the belt.

KWS included a zero-speed sensor and safety pull cable switch to protect personnel, equipment, and processes. When the zero-speed sensor detects a change in speed or zero speed, a signal is sent to a control panel to alert the operator of a malfunction. The safety pull cable switch can be activated by an operator if there is a potential safety or production issue, shutting down the belt conveyor.

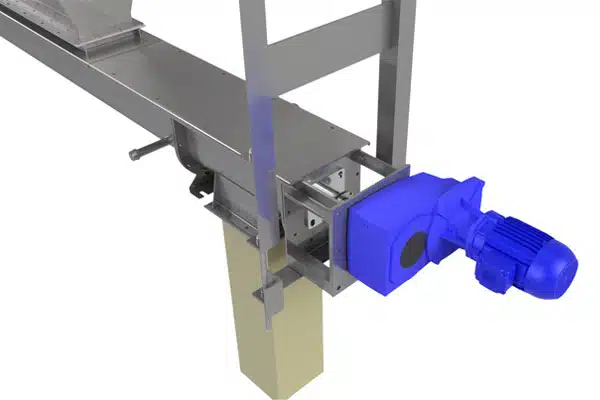

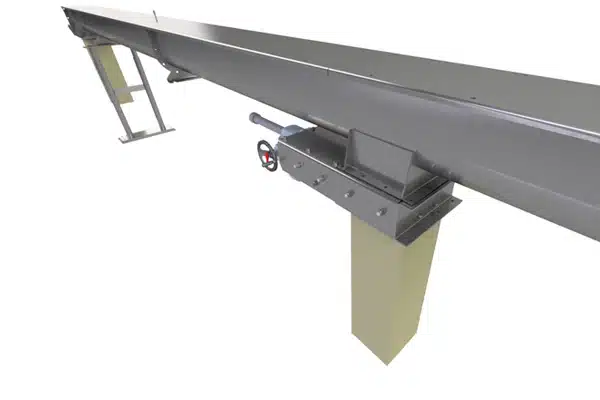

KWS provided a screw conveyor with discharge chutes, slide gate, inlet transition, and reversible drive. A KWS bulkhead trough end was used to put space between the drive and potential contamination or damage from the corrosive biosolids. Both the shaft seal and drive unit can be easily accessed for maintenance.

Flange gland seals were mounted to the outside of the trough ends to prevent biosolids from leaking out of the screw conveyor. Braided rope packing along with a lantern ring for grease purging of the seal is standard for biosolids conveying. The rope packing compresses around the shaft to create a positive seal.

Testimonial

"The KWS belt conveyor and screw conveyor work perfectly, and the installation went very well. Thank you for the start-up and training assistance."

Drake Gassett, Project Manager – Dugan & Meyers

Inlet Transition Fits to Belt Filter Press

Biosolids are Elevated to KWS Screw Conveyor

Screw Conveyor Receives Biosolids from Belt Conveyor

Bulkhead Trough End with Flanged Gland Seal Protects Drive Unit

Screw Conveyor Inlet Matches Discharge of Belt Conveyor

KWS Slide Gates and Chutes Direct Biosolids to Loadout Bins