Conveyor System for Torrefaction Process

General Description

Carbonized biomass is the process of converting biomass into a carbon-rich material through heat treatment, typically without oxygen. This process, known as carbonization or torrefaction, produces a solid, charcoal-like material. Volatile matter and water are removed from the biomass. The resulting material has a high carbon content and can be used in various applications, including soil amendment, energy production, and material science.

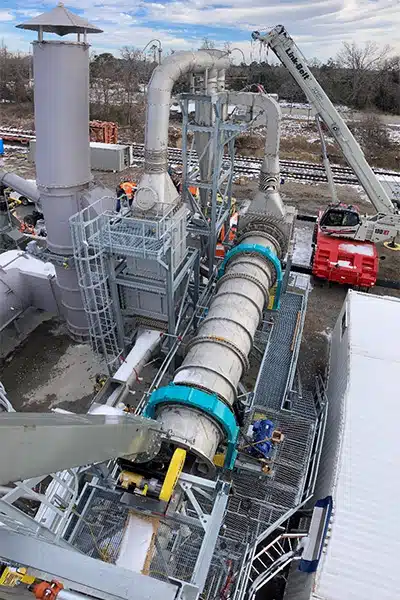

Through torrefaction, biomass in the form of wood residuals and agriculture waste is a fossil fuel substitute for many industries. A new facility is currently under construction to produce more than 15,000 tons per year of carbon-rich material. The process will produce a wide range of carbon-rich materials for the power and steel-making industries.

KWS emerged as the ideal partner for the new facility, bringing decades of engineering expertise and a proven track record of delivering high-performance bulk material handling equipment manufactured 100-percent in the United States.

Torrefaction Produces Carbon-Rich Materials from Biomass

Design Parameters

- Product Type: Wood Chips

- Design Temperature: Ambient

- Material Density: 10 to 13 Lbs. per Cubic Foot

- Capacity: 508 Cubic Feet per Hour

- Duty: Intermittent

KWS Advantages

KWS engineers collaborated closely with the technical team to develop a comprehensive material handling solution. Through an extensive design review process, KWS provided detailed 3D models and technical drawings that addressed the facility’s unique spatial and operational constraints.

The collaborative approach ensured a perfect equipment fit, minimizing installation challenges and maximizing operational efficiency. KWS’s ability to customize solutions and expedite manufacturing allowed the new facility to minimize downtime and quickly implement their new material handling system.

KWS Special Features

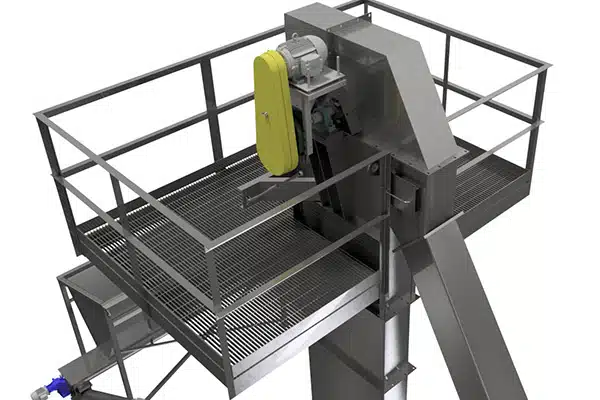

KWS engineered a custom loading hopper equipped with twin mass flow screw feeders positioned underneath to receive wood chip loads from a front-end loader. This specialized system precisely meters the material into an inclined transfer screw conveyor, ensuring consistent flow and optimal operational efficiency. The mass flow screw feeder incorporates an innovative design that maximizes efficiency when unloading material from large hoppers. At its core, this sophisticated system features a tapered cone strategically positioned on the center pipe of each screw directly beneath the hopper’s inlet opening. The combination of mass-flow and variable pitch created an optimal flow pattern that ensures material is drawn down uniformly across the entire length of the opening.

Bucket elevators are used to vertically transfer wood chips to the torrefaction process. Heavy duty in design and water-tight, the bucket elevators will run 24/7 to meet the needs of the process. KWS provided bucket elevator platforms for safe access to all sides of the head section and drive system. Platforms incorporate handrails, toe boards, guardrails, ladders, and an adjustable OSHA compliant, self-closing safety gate to create a safe and efficient working environment for personnel performing maintenance on the bucket elevators.

KWS also furnished several weigh belt conveyors featuring an integrated belt scale system designed for precision measurement. This advanced weighing technology continuously monitors and accurately quantifies the bulk material as it traverses the belt, enabling the delivery of exact bulk material quantities at predetermined feed rates. The system’s real-time weighing capabilities ensure consistent material flow and optimal production efficiency.

Customer Testimonial

“The KWS equipment is extremely well designed and manufactured. We installed everything with no fitment issues!”

Construction Manager – Torrefaction Plant

Wood Chips and Agriculture Waste are Biomass Used to Create Alternative Fuels

Hopper is Fed by a Front-End Loader to Start Process

Mass-Flow Screw Design Maximizes Metering Efficiency

Weigh Belt Precisely Measures Bulk Material Rate to Torrefaction Process

Bucket Elevator Transfers Wood Chips and Agriculture Waste Vertically and Discharges to Torrefaction Process

Platforms Provide Safe Access to All Sides of Bucket Elevator Head Section