Inclined Screw Feeder for Metering Sprouted Grain at Bakery

General Description

Sprouted wheat is wheat grain that has been put in water and allowed to sprout. Sprouted grain bread is healthier for us than white and wheat bread because it uses the whole grain. During the sprouting process, proteins and carbohydrates in the grain are broken down, thus increasing vitamin content. It also has a low glycemic index and is easier to digest. Nutrients are absorbed into the body and therefore not lost in the digestive track.

A bakery received sprouted wheat grain in bulk bags and needed to precisely meter it to a hopper to begin the bread making process. KWS provided a unique, food grade solution for the application.

Sprouted Wheat Grain is Metered from Bulk Bags

Design Parameters

- Product Type: Sprouted Wheat Grain

- Material Density: 33 Lbs. per Cubic Foot

- Capacity: 455 Cubic Feet per Hour

- Duty: 24 Hours per Day, 7 Days per Week

KWS Advantages

Engineers at KWS have the education, knowledge, and experience to solve a multitude of bulk material handling applications. Metering and conveying food products require special knowledge of food industry standards. Most food ingredient applications necessitate stainless steel construction with special welding and polishing. No pits or crevices are allowed in the areas where food products are in contact with conveying surfaces. Every engineer at KWS is trained to understand food industry applications and to provide the correct design.

KWS Special Features

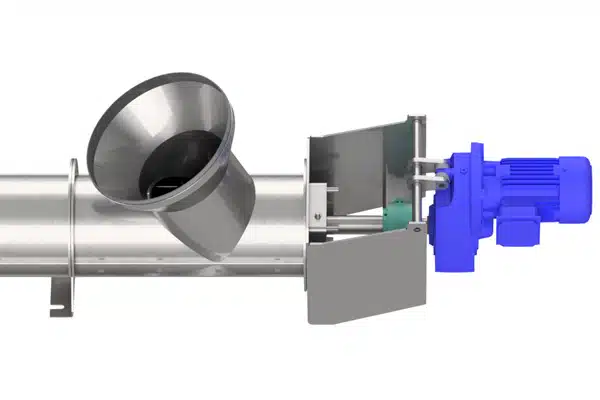

KWS provided a special inlet to match the incline of the screw feeder and the discharge of the bulk bag unloader. The inlet was round and tapered down to match the tubular housing for the screw feeder. KWS added a sock bead on the inlet to attach a flexible connection to the bulk bag unloader. The discharge of the inclined screw feeder also had a sock bead for attachment of a flexible connection to downstream equipment. To provide accurate metering, the screw conveyor had variable pitch flighting under the inlet area to accurately meter the sprouted wheat grain up the incline.

No pits or crevices were allowed in the design and construction of the new screw feeder. The complete screw feeder was constructed from 304 stainless steel with all internal surfaces polished to 150-grit finish. All welds were continuous and ground smooth with the base metal. Drive and end shafts were welded in each end of the screw. KWS has developed a very special drive and trough end arrangement for food grade applications. The design allows for the use of pillow block bearings on each end and a floating, torque arm drive arrangement. Food grade shaft seals prevent wheat grain from leaking from the feeder.

Testimonial

"We are very happy with the inclined screw feeder from KWS. The KWS equipment is very robust and will handle the duty cycle that the original flexible screw conveyor could not handle. Thanks for creating a long-term solution for us."

Project Engineer – Bakery Company

Special Inlet with Flexible Connections Match Bulk Bag Unloader

New KWS Screw Feeder is Constructed from 304 Stainless Steel with Food Grade Finish

Variable Pitch Flighting Accurately Meters Sprouted Grain

Floating Torque Arm Drive Arrangement is Part of Robust Design