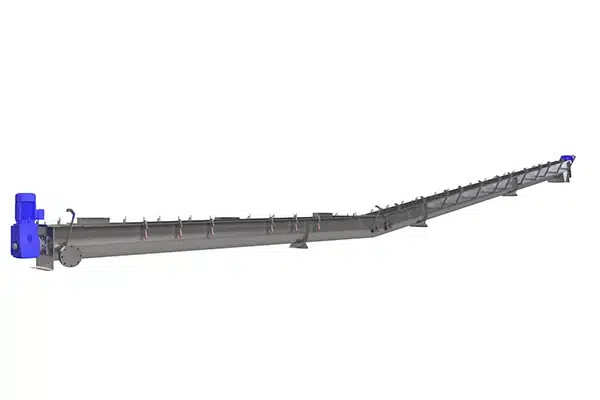

Inclined Tandem Screw Conveyor for Welch Foods Inc.

General Description

Welch Foods started over 140 years ago when Thomas Bramwell Welch chose to serve grape juice instead of wine at his church in Concord, MA. Welch was a pioneer in pasteurizing bottled fruit juice using Concord grapes, laying the foundation for a new industry. After its introduction at the Chicago World’s Fair in 1893, Welch’s Grape Juice quickly became a national favorite.

The plant in Westfield, NY produces grape juice from grapes grown by farmers that make up the National Grape Co-Operative. Concord and Niagara grapes are grown across New York, Pennsylvania, Ohio, Michigan, and Washington states. A tandem screw conveyor was required to replace a worn-out drag conveyor to transfer grape stems from finishing machines to truck load out. The grape stems are sold as a feed additive for animals.

KWS Tandem Screw Conveyor Conveys Grape Stems to Load Out

Design Parameters

- Product Type: Grape Stems

- Material Density: 25 to 30 Lbs. per Cubic Foot

- Conveyor System Capacity: 204 Cubic Feet per Hour

- Duty: Intermittent

KWS Advantages

Engineers from KWS analyzed the application and recommended a tandem screw conveyor to replace the existing drag conveyor. Screw conveyors provide a very simple solution and require less maintenance when compared to drag conveyors. Since there were existing space constraints, the new screw conveyor system was modeled to make sure it fit perfectly under the finishing machines. As a result, the equipment was installed with no issues.

KWS Special Features

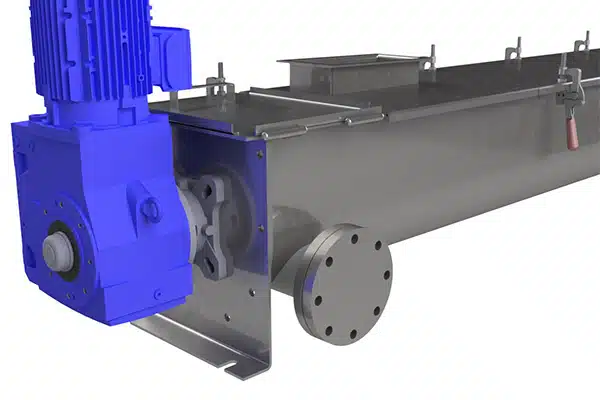

KWS designed a tandem screw conveyor system featuring a horizontal screw conveyor feeding directly into an inclined screw conveyor, each powered by its own gearmotor. A hanger with a UHMW hanger bearing supported each screw. KWS manufactured the new conveyors from 304 stainless steel to resist corrosion and utilized ribbon flighting to prevent grape stems from sticking to the screw and pipe.

A 4-inch drain connection was located at the inlet end of the horizontal screw conveyor on the non-carrying side. A 1-inch flushing port was located directly opposite of the drain connection to eliminate plugging. The tandem screw conveyor system is completely enclosed and washed down periodically.

The screw conveyor covers were hinged with heavy-duty backstops and toggle clamps for easy cleaning. Each cover featured a single safety interlock switch to minimize risk and injury when opening. Interlock switches shut off the equipment if an operator attempts to open the covers during operation.

Testimonial

"The equipment is running 24/7 with no issues! KWS was easy to work with and very professional."

Adam Mikulcik, Senior Project Engineer – Welch Foods

Horizontal Screw Conveyor Feeds Directly into Inclined Screw Conveyor

Hinged Covers with Safety Interlock Switches Shut Off Equipment When Covers are Opened

Wash Water is Drained Through 4-Inch Connection