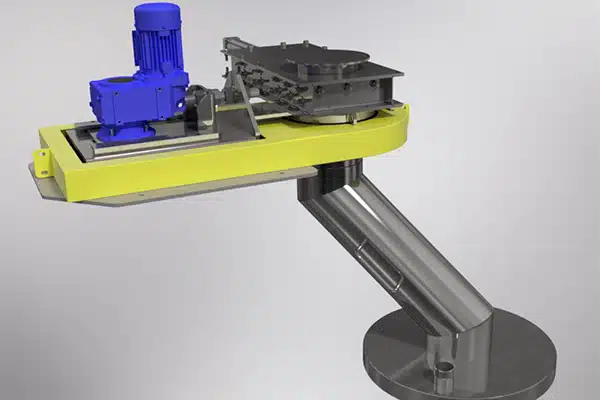

KWS Motorized Diverter Chute

General Description

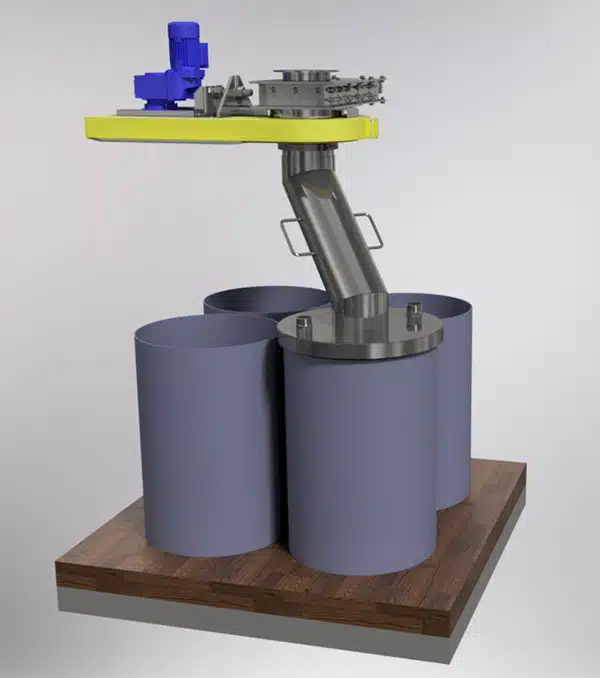

The KWS Motorized Diverter Chute is designed to manage the conveying and loadout of bulk solids efficiently and reliably. Unlike traditional methods that often overlook the importance of these systems, this innovative solution ensures that materials are directed to specific locations with minimal operator intervention. The diverter chute can seamlessly and precisely feed various hoppers, dumpsters, trucks, bulk bags, or bins, allowing for level filling and the capability to service multiple destinations in a single operation.

KWS Motorized Diverter Chute Seamlessly and Precisely Fills Containers, Hoppers, Trucks, and Bulk Bags

KWS Advantages

The KWS Motorized Diverter Chute can be controlled remotely and automatically, significantly reducing the need for manual intervention. Safety is enhanced for operators by minimizing exposure to potentially hazardous environments. This system provides precise control over material flow, enabling the diverter chute to efficiently redirect materials to multiple destinations with accuracy. By streamlining operations and improving safety, the KWS Motorized Diverter Chute is an essential component for optimizing bulk material handling processes in various industrial applications.

KWS Special Features

The simple pivoting mechanism system allows for smooth and controlled pivoting of the chute. This mechanism ensures that the chute can be easily adjusted to direct materials precisely where needed, enhancing operational efficiency. The use of UHMW slide retainers supports the pivoting action, providing low-friction movement.

Integrated slide gates serve as effective control mechanisms for managing the flow of bulk materials. They can be opened or closed to divert or stop material flow, acting as cut-off valves or emergency shut-off gates. This feature enhances operational flexibility and safety, allowing for quick adjustments based on system needs.

KWS Motorized Diverter Chute Can Be Controlled Remotely and Automatically, Significantly Reducing Manual Intervention