Screw Feeder for Metering Coffee Beans at Gaviña & Sons Vernon, CA

General Description

Coffee beans are among the highest produced and most valuable agricultural crops in the world. The tropical belt along the equator is where the world’s coffee is produced and mainly comes from South America and Central Africa. The United States is the largest importer of coffee at around 5.5 billion dollars’ worth of coffee beans each year.

KWS Screw Feeder Meters Green Coffee Beans to Roasting Process

The Gaviña family has been growing coffee beans since 1870. Gaviña & Sons began roasting and brewing high quality coffee in 1967 in their Vernon, CA facility, encompassing over 240,000 square feet. Green Arabica coffee beans are received from specific growing regions, then processed and roasted to perfection.

Due to continued demand for their coffee, Gaviña & Sons increased production and needed a way to accurately meter raw coffee beans from initial storage to the roasting process. With space constraints and a long transfer distance, a creative solution was necessary.

Design Parameters

- Product Type: Green Coffee Beans

- Material Density: 40 Lbs. per Cubic Foot

- Capacity: 500 Cubic Feet per Hour

- Duty: 24 Hours per Day, 7 Days per Week

KWS Advantages

Gaviña & Sons and KWS collaborated to provide a solution for metering coffee beans without degrading the integrity of the beans. KWS is an expert in conveyance of food products and was able to provide many different solutions for the application. High quality and cleanliness were of most importance for Gaviña & Sons to ensure the beans maintain their flavor.

KWS Special Features

Long Inlet Opening Properly Empties Entire Length of Storage Bin

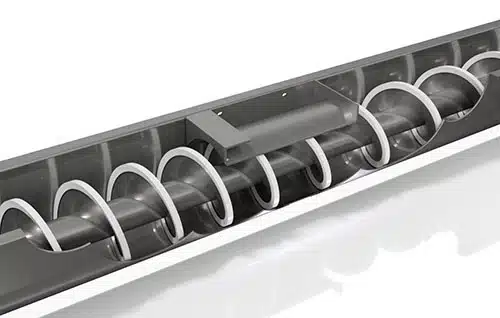

KWS provided a screw feeder to meter green coffee beans from a storage bin to the roasting process. The screw feeder was designed with a long open inlet to properly empty the entire length of the storage bin. Variable pitch flighting was used to evenly meter the coffee beans for a first-in, first-out sequence which is vital to keeping the coffee beans fresh.

The full length of the feeder screw was equipped with UHMW flight edging and supported in the bottom of the trough. Flight edging eliminates hanger bearings which present cleanliness problems. Also, flight edging provides better trough clean out, leaving no product behind. Elimination of the gap between the flight edging and trough drastically reduces degradation of the coffee beans. A waste pack seal was used on the tail end of the screw feeder to ensure no product leakage. The drive unit was turned to the 3 o’clock position to prevent interference with the storage hopper.

Testimonial

"The flight edging has worked great for us, and we look forward to buying more conveyors from KWS."

Leo Fandino – Gaviña & Sons

Screw with UHMW Flight Edging is Supported in Bottom of Trough

Flight Edging Provides Better Trough Clean Out and Reduces Degradation of Coffee Beans