Special Rack & Pinion Slide Gate for Extreme Head Load

General Description

Lhoist North America (LNA) is one of the world’s largest suppliers of lime, limestone, and clay products. These products ultimately end up in industries such as: iron and steel, chemical production, water treatment, agriculture, pulp and paper, glass, as well as building materials.

Lhoist prides itself on quality standards unsurpassed by others. Stringent product standards, best practices on community and ecology, and unsurpassed technical service are just a few of Lhoist’s core values.

Bulk materials processed and stored at Lhoist facilities are conveyed to load out areas for transport by rail car or bulk truck. These bulk materials are stored in large silos and require a method for flow control. Slide gates are commonly used for controlling the flow rate of bulk materials. KWS provided several special, heavy-duty rack and pinion slide gates for precise disbursement. At Lhoist, KWS is the preferred engineered solution provider.

Slide Gates are Located Under Silos for Flow Control

Design Parameters

- Product Type: Limestone Granules

- Material Density: 50 to 60 Lbs. per Cubic Foot

- Duty: 24 Hours Per Day, 7 Days Per Week

KWS Advantages

KWS met with Lhoist on site to discuss the application and determine a long-term solution. With all conveyor equipment and accessories, consideration of safety factors as well as robust production requirements were noted and recorded. Key measurements of the existing silo and special flange pattern were documented. KWS field engineers measured the equipment footprint and verified every critical dimension including material thickness, bolt patterns, and overall dimensions. KWS provides valuable engineering services to our customers.

KWS Special Features

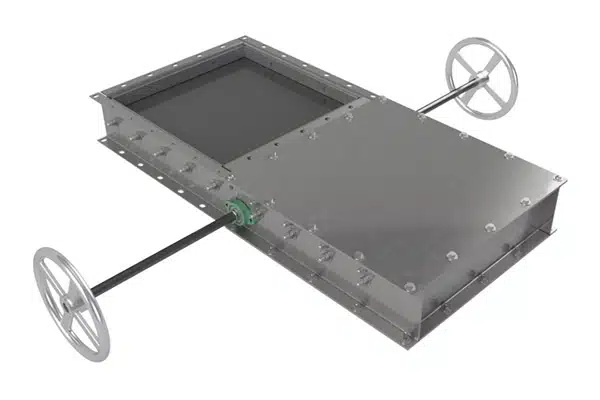

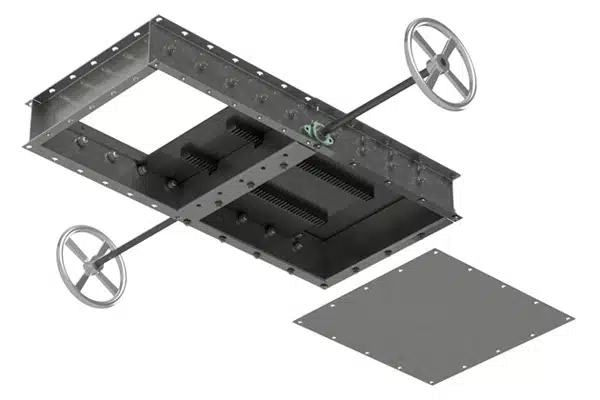

The new KWS slide gates were designed to operate with a massive hopper full of lime. The force on the gate was calculated at over 5,000-lbs. KWS increased the slide gate blade thickness to resist deflection from the headload of material. The slide plate and retainers were constructed from abrasion resistant steel to provide years of uninterrupted service. The slide plate was supported by rollers located on very close centers. Dual hand wheels powered the rack-and-pinion gates. The robust design put the slide gate at well over three hundred pounds.

The design created by KWS was the perfect solution for Lhoist. With the highest quality standards in the industry, unique, creative design, and rugged heavy-duty construction, KWS provides features and benefits that exceed expectations and provide real customer satisfaction.

Testimonial

"The heavy-duty KWS slide gate was manufactured perfectly, it fit the exact footprint and will last for many, many years."

Mark Herzog, Maintenance Planner – Lhoist North America

Hand Wheels Operate Rack-and-Pinion Gearing for Opening and Closing Slide Plate

Gate is Completely Enclosed for Safe Operation